Press Room

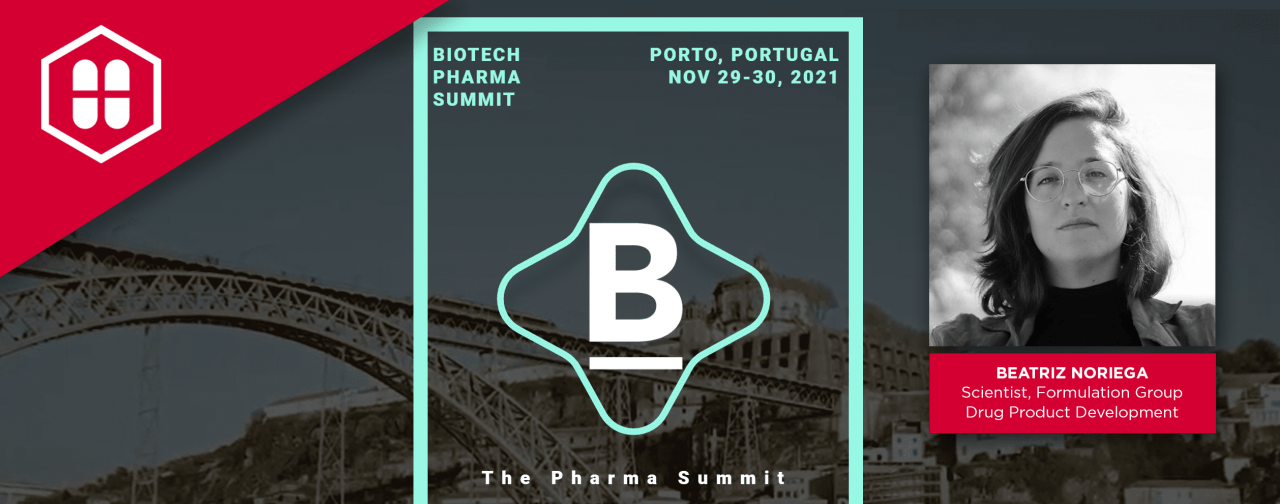

IRDD 2021 - The BioTech Pharma Summit

Hovione is present at the BioTech Pharma Summit taking place in Oporto, Portugal. Our expert in drug product develpment will present on day 1 in the Inhalation & Respiratory Drug Delivery stream. Join us.

Hovione Presentation

Day 1 - Monday, November 29th 2021 | 11:30 - 12:00

Stream: Inhalation & Respiratory Drug Delivery

Session: Inhalation Formulation Solutions & Technology

High Dosage DPI – formulation and process development considerations

Presenter: Beatriz Noriega Fernandes, Scientist, Formulation Group - Drug Product Development at Hovione

Abstract:

Biopharmaceuticals represent the most promising and fastest growing field in the pharmaceutical area. These therapeutics show very high specificity and potency at relatively low concentrations and enable the treatment of otherwise untreatable diseases. One of the main challenges when developing a spray dried biopharmaceutical formulation for Dry Powder Inhalers is the generation of a stable aerosol able to reach the lungs while preserving the integrity of the biopharmaceutical, rendering it safe and effective. In this presentation the most promising alternatives to freeze drying with focus on particle engineering methods for dry powder inhalation such as spray drying will be discussed. Case-studies will be provided to support participants diving into specific examples of selected topics.

The presentation will provide participants the opportunity to learn about the integration of technologies and capabilities to take a Dry Powder Inhalation product development from early-stage development to commercial stage products.

If you would like to discuss with us your projects and to find how Hovione can help, schedule a meeting with us. Our team will be pleased to meet you.

You might be interested in: